Thermal Grizzly has expanded its lineup of cooling materials with the launch of Minus Pad Extreme 2 and Minus Pad High Compression (HC) thermal pads. These new additions aim to provide improved performance, flexibility, and ease of use across a range of PC cooling applications, including graphics card and CPU cooling setups.

The Minus Pad Extreme 2 serves as the direct successor to the company’s original Minus Pad Extreme, bringing a new material formulation designed to enhance the balance between performance and cost. According to Thermal Grizzly, the latest pad maintains the high thermal conductivity levels of its predecessor while optimizing its price-to-performance ratio.

The main change lies in the updated composition, which combines aluminum oxide, aluminum hydroxide, and aluminum powder. These materials are integrated using particles of different sizes to fill even the smallest gaps within the pad’s structure. This design approach improves thermal contact by reducing air pockets between the heat source and the heatsink, ultimately helping to lower interface resistance.

Another improvement is the softer consistency of the new pad, which allows it to conform more effectively to uneven surfaces. This flexibility ensures consistent contact pressure, an important factor for maintaining stable thermal performance over time. Despite the changes, the compressibility of the Minus Pad Extreme 2 remains similar to that of the original version and the company’s Minus Pad Basic series.

The Minus Pad Extreme 2 is available in multiple sizes and thickness options. Customers can choose between 120 × 20 mm and 100 × 100 mm sizes, with thicknesses ranging from 0.5 mm up to 3 mm. The pad is electrically non-conductive and does not require curing, making installation simpler for both enthusiasts and professionals.

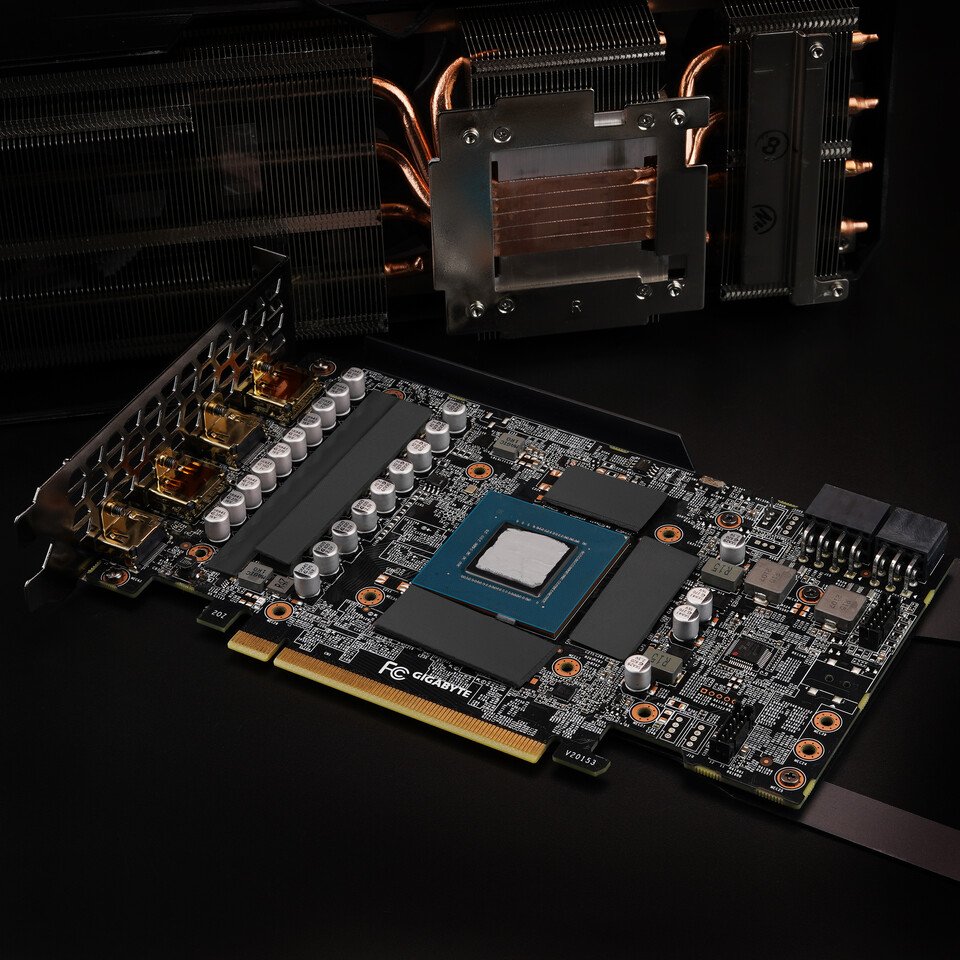

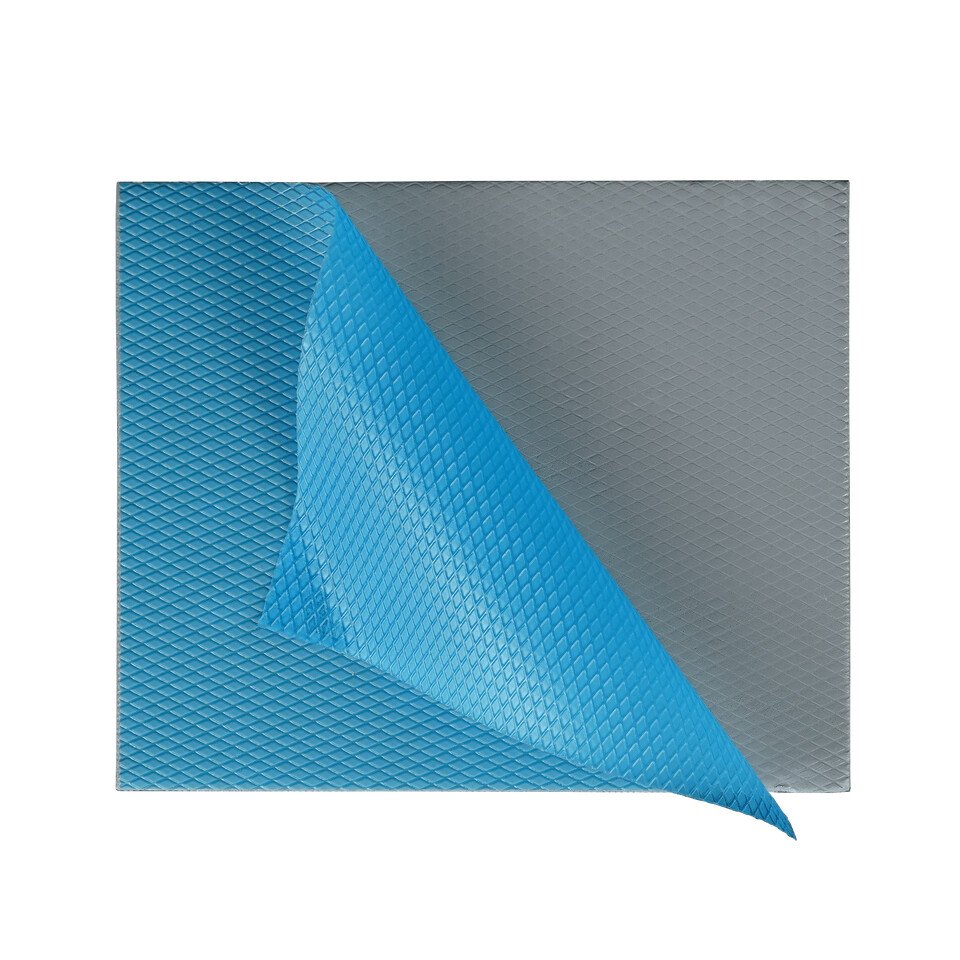

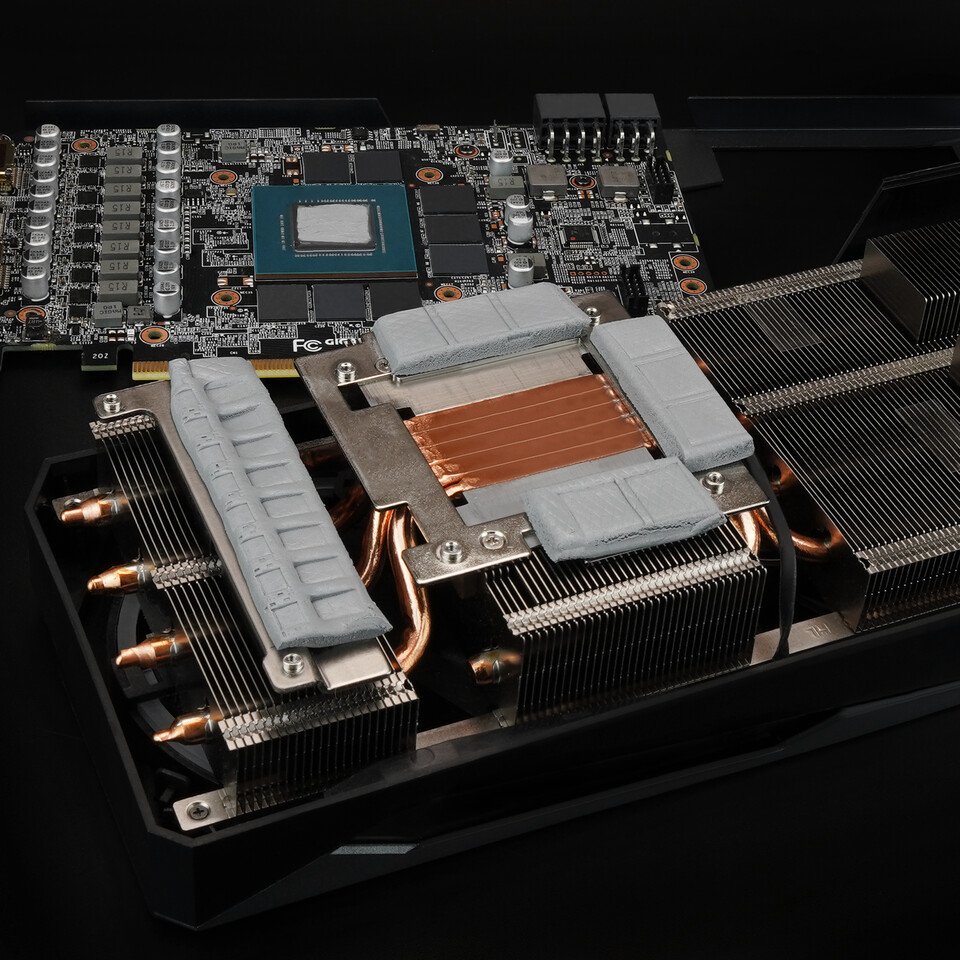

Alongside the new Extreme 2 model, Thermal Grizzly also unveiled the Minus Pad High Compression (HC) series. This range focuses on versatility and adaptability, offering very high compressibility without compromising on thermal conductivity. The HC pads are particularly useful in builds where a single pad must bridge varying component heights—such as during GPU water block installations or when replacing factory thermal pads on VRAM modules and voltage regulators.

Thermal Grizzly notes that the thermal conductivity of the HC pads remains stable under compression and may even increase with higher contact pressure. This makes them ideal for applications where exact pad thicknesses are unknown, simplifying the installation process.

The Minus Pad High Compression series is available in 120 × 100 mm sheets, with thickness options from 1 mm to 5 mm. Like the Extreme 2, these pads are electrically non-conductive and designed for consistent performance across multiple contact surfaces.

With these additions, Thermal Grizzly continues to strengthen its portfolio of thermal interface materials, addressing the needs of PC builders, overclockers, and professionals seeking reliable and efficient cooling solutions for high-performance systems.